FAQs

- Home

- FAQs

High Expansión

FAQs, High Expansión

The volume of foam produced is the product of the flow of water mixed with foam that comes, by the expansion ratio.

· In the case of GAE-250, at a pressure of 4 bar is:

23x 816 = 190 128 l / min.

· For the GAE 400, at a pressure of 4 bar:

378 x 820 = 309 960 l / min.

Always above the risk to be flooded.

According to the NFPA-11-A, the volume of foam produced by the generator, to be discounted 15%, by that coefficient.

For relatively small enclosures, in case of a real fire, hot air, mixed with aerosols, dust, etc., tends to rise, and since generators should be located at the top of the premises is to occur if making a bubble of hot air foam, the expansion force of the air is greater than the surface tension of the microfilm and the foam breaks, bursting so a much smaller amount of foam is achieved. It is therefore desirable that the foam forms with clean air at room temperature, it is necessary to study the location of generators and try to get most fulfilling this condition.

About time and influences the room temperature, will gradually bursting bubbles, producing clear, decanting the water into the ground where it can be removed more easily.

Low expansion

FAQs, Low Expansion

It depends on the height of your location, but for a situation over 3m., Relative to ground level deck area of 9 square meters, although the projection is circular.

· The amount of foam produced is the product of the flow, by the expansion ratio.

· For this model, UAS, the flow rate at 3 bars, is 70 l / min.

· The expansion ratio is from 1 to 6 (depending on the type of foam concentrate), so the volume of foam produced is:

· 70 x 6 = 420 l / min of foam.

Foam Concentrate Tank

FAQs, Foam Concentrate Tank

The proportioning venturimétricos have to work horizontally, which is its normal position, not vertical or inclined.

In the case of the proportioning mod. SE-Z-ES and SE, the suction will be at the top while in the case where the mod. SE-PRO, the vacuum remains at the bottom.

To prevent foam formation when filling , since otherwise , if the foam is poured freely by dropping a single orifice from a height a large amount of foam which would prevent filling in a single operation would occur on deposit . With the dip tube is achieved by filling the foam from the bottom , so that this problem does not occur.

The foam is slightly evaporable, if the tank is not full at all, said vapors just rusting tank wall, said oxidation is slow, because inside the tank is painted in epoxy, therefore and for greater longevity of the foam, in order to reduce as much as possible to the surface in contact with the atmosphere, an atmospheric tank containing foam is much better that it is always fully booked.

The suction tube is just biased and not in contact with the bottom, but reaches about 50 mm from it, this is to prevent suction positos, gels, etc. oxide plates, which eventually are deposited in the tank bottom.

The ability of the same, when constructed, is already taken into account this “loss” of volume.

Bladder Tank

FAQs, Bladder Tank

Each reservoir, with the foam inside the membrane, is provided with technical sheets for the filling process.

You must explicitly follow these instructions in order to perform a correct filling. Otherwise you run the risk of seriously damaging the membrane.

As the operating time of the installation takes place, the inside of the membrane is emptied and the space between the membrane and the inner wall of the tank is filled with water in the same amount as foam exits the interior of the membrane.

Where appropriate a very prolonged operation would empty the tank of foam concentrate and water-filled encounter.

By proportioning only pass water because he can not leave foam inside the tank, by exhaustion, and so until the installation will not stop ie it will be pulling water, no foam mixture.

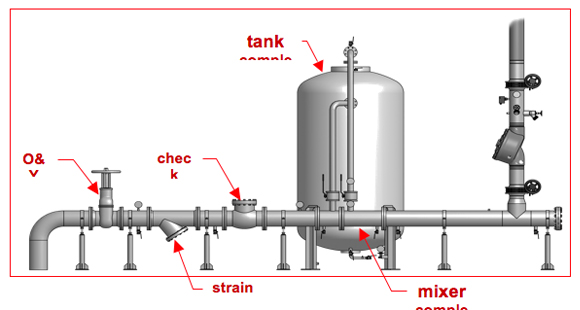

They have two functions, draw the line foam and sampling of water mixed with foam, for observation by refractometer or conductivity of the mixing ratio.

Depends primarily on the flow and diameter of each proportioner is designed for a maximum flow rate – minimum flow between a chosen percentage correct dosage, usually 3% or 6% is guaranteed. The more flow rate the pressure drop. Normally a maximum flow for a given diameter of proportioning, the maximum pressure drop is between 0.9 and 1.1 bars.

In our catalog you will see the pressure drop for each proportioning diameter, depending on the desired flow rate.

General

FAQs, General

Below we show a relation of frequently asked questions about the general aspects of the web.

One of the most freequentes doubt this site is how I buy.

1. On the internet

2. By phone

3. In our commercial business, contact a commercial

Medium Expansion

FAQs, Medium Expansion

Whenever a point suitable protection, such a packaging machine, sanding a bank, a small store, a pump etc.. in general for any type of risks situated.

· The UME 27, threaded ¾ “, a flow rate of 47 l / min at 3 bar, and an expansion ratio of 1-58 (depending on the type of foam), gives a volume of foam: 47 x 58 = 2,726 l / min.

· The UME 45, threaded 1 “, a flow rate of 78 l / min at 3 bar and an expansion ratio of 1-60 (depending on the type of foam), gives a volume of foam: 78 x 50 = 4680 l / min.

No, there is just enough reaction and anchoring the four flange bolts, with no other support.

When is convenient protecting cubeto 15-20 º tilt towards the ground, for a better movement of the froth.

Proportioners

FAQs, Proportioners

The proportioning venturimétricos have to work horizontally, which is its normal position, not vertical or inclined.

In the case of the proportioning mod. SE-Z-ES and SE, the suction will be at the top while in the case where the mod. SE-PRO, the vacuum remains at the bottom.

Proportioner serve for vacuuming can continue normally, even in case that the suction tube was deposited flat on the tank bottom.

It is also common, finish the end of the suction tube on a bias, ie on sloping for the same reason (with sprat) court.

About 30% -35% (inlet pressure, outlet pressure regarding)

In principle proportioner specifically machined to flow Desire, if you want to vary the flow rate in the sense of wanting to spend more flow, simply change the cone input, other suitable to the flow we want also the calibrated diameter suction hole, it will reset it so that we continue to give the percentage of constant mixing.

This field in the maximum flow that allows us to model each proportioning, whether the desired rate can exceed that given a particular model of proportioning, then no choice but to switch to the appropriate flow model for the defendant.

The flow of a particular model of proportioning, you can also decrease, changing the input cone one suited to the needs requested, but then the suction hole must make it smaller, by a cap.

SE-A

To prevent foam formation when filling , since otherwise , if the foam is poured freely by dropping a single orifice from a height a large amount of foam which would prevent filling in a single operation would occur on deposit . With the dip tube is achieved by filling the foam from the bottom , so that this problem does not occur.

The foam is slightly evaporable, if the tank is not full at all, said vapors just rusting tank wall, said oxidation is slow, because inside the tank is painted in epoxy, therefore and for greater longevity of the foam, in order to reduce as much as possible to the surface in contact with the atmosphere, an atmospheric tank containing foam is much better that it is always fully booked.

The suction tube is just biased and not in contact with the bottom, but reaches about 50 mm from it, this is to prevent suction positos, gels, etc. oxide plates, which eventually are deposited in the tank bottom.

The ability of the same, when constructed, is already taken into account this “loss” of volume.

SE-DA

To prevent foam formation when filling , since otherwise , if the foam is poured freely by dropping a single orifice from a height a large amount of foam which would prevent filling in a single operation would occur on deposit . With the dip tube is achieved by filling the foam from the bottom , so that this problem does not occur.

The foam is slightly evaporable, if the tank is not full at all, said vapors just rusting tank wall, said oxidation is slow, because inside the tank is painted in epoxy, therefore and for greater longevity of the foam, in order to reduce as much as possible to the surface in contact with the atmosphere, an atmospheric tank containing foam is much better that it is always fully booked.

The suction tube is just biased and not in contact with the bottom, but reaches about 50 mm from it, this is to prevent suction positos, gels, etc. oxide plates, which eventually are deposited in the tank bottom.

The ability of the same, when constructed, is already taken into account this “loss” of volume.

SE-ES

The proportioning venturimétricos have to work horizontally, which is its normal position, not vertical or inclined.

In the case of the proportioning mod. SE-Z-ES and SE, the suction will be at the top while in the case where the mod. SE-PRO, the vacuum remains at the bottom.

Proportioner serve for vacuuming can continue normally, even in case that the suction tube was deposited flat on the tank bottom.

It is also common, finish the end of the suction tube on a bias, ie on sloping for the same reason (with sprat) court.

About 30% -35% (inlet pressure, outlet pressure regarding)

In principle proportioner specifically machined to flow Desire, if you want to vary the flow rate in the sense of wanting to spend more flow, simply change the cone input, other suitable to the flow we want also the calibrated diameter suction hole, it will reset it so that we continue to give the percentage of constant mixing.

This field in the maximum flow that allows us to model each proportioning, whether the desired rate can exceed that given a particular model of proportioning, then no choice but to switch to the appropriate flow model for the defendant.

The flow of a particular model of proportioning, you can also decrease, changing the input cone one suited to the needs requested, but then the suction hole must make it smaller, by a cap.

SE-GAE 100

Always above the risk to be flooded.

According to the NFPA-11-A, the volume of foam produced by the generator, to be discounted 15%, by that coefficient.

For relatively small enclosures, in case of a real fire, hot air, mixed with aerosols, dust, etc., tends to rise, and since generators should be located at the top of the premises is to occur if making a bubble of hot air foam, the expansion force of the air is greater than the surface tension of the microfilm and the foam breaks, bursting so a much smaller amount of foam is achieved. It is therefore desirable that the foam forms with clean air at room temperature, it is necessary to study the location of generators and try to get most fulfilling this condition.

About time and influences the room temperature, will gradually bursting bubbles, producing clear, decanting the water into the ground where it can be removed more easily.

SE-GAE 250/400

The volume of foam produced is the product of the flow of water mixed with foam that comes, by the expansion ratio.

· In the case of GAE-250, at a pressure of 4 bar is:

23x 816 = 190 128 l / min.

· For the GAE 400, at a pressure of 4 bar:

378 x 820 = 309 960 l / min.

Always above the risk to be flooded.

According to the NFPA-11-A, the volume of foam produced by the generator, to be discounted 15%, by that coefficient.

For relatively small enclosures, in case of a real fire, hot air, mixed with aerosols, dust, etc., tends to rise, and since generators should be located at the top of the premises is to occur if making a bubble of hot air foam, the expansion force of the air is greater than the surface tension of the microfilm and the foam breaks, bursting so a much smaller amount of foam is achieved. It is therefore desirable that the foam forms with clean air at room temperature, it is necessary to study the location of generators and try to get most fulfilling this condition.

About time and influences the room temperature, will gradually bursting bubbles, producing clear, decanting the water into the ground where it can be removed more easily.

SE-MXC-I

Each reservoir, with the foam inside the membrane, is provided with technical sheets for the filling process.

You must explicitly follow these instructions in order to perform a correct filling. Otherwise you run the risk of seriously damaging the membrane.

As the operating time of the installation takes place, the inside of the membrane is emptied and the space between the membrane and the inner wall of the tank is filled with water in the same amount as foam exits the interior of the membrane.

Where appropriate a very prolonged operation would empty the tank of foam concentrate and water-filled encounter.

By proportioning only pass water because he can not leave foam inside the tank, by exhaustion, and so until the installation will not stop ie it will be pulling water, no foam mixture.

They have two functions, draw the line foam and sampling of water mixed with foam, for observation by refractometer or conductivity of the mixing ratio.

Depends primarily on the flow and diameter of each proportioner is designed for a maximum flow rate – minimum flow between a chosen percentage correct dosage, usually 3% or 6% is guaranteed. The more flow rate the pressure drop. Normally a maximum flow for a given diameter of proportioning, the maximum pressure drop is between 0.9 and 1.1 bars.

In our catalog you will see the pressure drop for each proportioning diameter, depending on the desired flow rate.

SE-SME

No, there is just enough reaction and anchoring the four flange bolts, with no other support.

When is convenient protecting cubeto 15-20 º tilt towards the ground, for a better movement of the froth.

SE-UAS

It depends on the height of your location, but for a situation over 3m., Relative to ground level deck area of 9 square meters, although the projection is circular.

· The amount of foam produced is the product of the flow, by the expansion ratio.

· For this model, UAS, the flow rate at 3 bars, is 70 l / min.

· The expansion ratio is from 1 to 6 (depending on the type of foam concentrate), so the volume of foam produced is:

· 70 x 6 = 420 l / min of foam.

SE-UME

Whenever a point suitable protection, such a packaging machine, sanding a bank, a small store, a pump etc.. in general for any type of risks situated.

· The UME 27, threaded ¾ “, a flow rate of 47 l / min at 3 bar, and an expansion ratio of 1-58 (depending on the type of foam), gives a volume of foam: 47 x 58 = 2,726 l / min.

· The UME 45, threaded 1 “, a flow rate of 78 l / min at 3 bar and an expansion ratio of 1-60 (depending on the type of foam), gives a volume of foam: 78 x 50 = 4680 l / min.

SE-VZ

About 30% -35% (inlet pressure, outlet pressure regarding)

In principle proportioner specifically machined to flow Desire, if you want to vary the flow rate in the sense of wanting to spend more flow, simply change the cone input, other suitable to the flow we want also the calibrated diameter suction hole, it will reset it so that we continue to give the percentage of constant mixing.

This field in the maximum flow that allows us to model each proportioning, whether the desired rate can exceed that given a particular model of proportioning, then no choice but to switch to the appropriate flow model for the defendant.

The flow of a particular model of proportioning, you can also decrease, changing the input cone one suited to the needs requested, but then the suction hole must make it smaller, by a cap.

SE-Z

The proportioning venturimétricos have to work horizontally, which is its normal position, not vertical or inclined.

In the case of the proportioning mod. SE-Z-ES and SE, the suction will be at the top while in the case where the mod. SE-PRO, the vacuum remains at the bottom.

Proportioner serve for vacuuming can continue normally, even in case that the suction tube was deposited flat on the tank bottom.

It is also common, finish the end of the suction tube on a bias, ie on sloping for the same reason (with sprat) court.

About 30% -35% (inlet pressure, outlet pressure regarding)

In principle proportioner specifically machined to flow Desire, if you want to vary the flow rate in the sense of wanting to spend more flow, simply change the cone input, other suitable to the flow we want also the calibrated diameter suction hole, it will reset it so that we continue to give the percentage of constant mixing.

This field in the maximum flow that allows us to model each proportioning, whether the desired rate can exceed that given a particular model of proportioning, then no choice but to switch to the appropriate flow model for the defendant.

The flow of a particular model of proportioning, you can also decrease, changing the input cone one suited to the needs requested, but then the suction hole must make it smaller, by a cap.